Okisijeni Jenareta nePressure Swing Adsorption (PSA)

• Idiki yetsoka, nguva pfupi yekuvaka;

• Kuderera kwekudyara uye mari yekushandisa;

• Nyore kutanga-up uye kumira;

• High degree of otomatiki, zvizere otomatiki uye unmanned kushanda;

• Kushanda pakupisa kwekamuri uye kuderera kwepasi nekuchengetedzwa kwepamusoro uye kuvimbika;

• Nzira iri nyore uye iri nyore kuchengetedza;

• Kuchena kweokisijeni ye90 kusvika ku94% (yakasara iAr + N2)

• Kugadzirwa kweokisijeni ndeye 4 - 100 Nm3 / h.

| Electric Steelmaking | 93% | Blast Furnace Iron-kugadzira | 90% |

| Welding Kucheka | 94% | Gold Melting | 93% |

| Sewage Treatment | 90% | Kurima | 90% |

| Girazi Processing | 90%~94% | Bronze Craft | 94% |

| Mwenje Kugadzirwa | 93% | Kiln Combustion Aid | 90%~94% |

| Kemikari Kuvirisa | 90% | Carbon Black Processing | 90% |

| Chemical Fertilizer Indasitiri | 93% | Pharmaceutical Manufacturing | 90% |

| Pepa Kugadzira Indasitiri | 90%~93% | Waste Incineration | 90% |

| Ozone Generation | 90%~95% | Medical Care | 90%~94% |

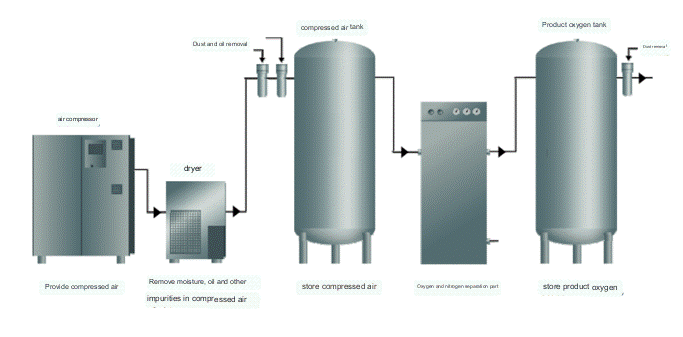

PSA zvirimwa zvinogadzira okisijeni zvinoshandisa mhepo yakadzikama sechinhu chakabikwa, chakachengeteka uye chisina kusvibiswa. Mhepo yemumhepo inobviswa, inocheneswa uye yakaomeswa, uye yakamanikidzwa adsorption uye decompression desorption inoitwa mu adsorber, uye hapana magasi anokuvadza anogadzirwa.

PSA okisijeni kugadzira michina inoumbwa nezvinhu zviri nyore uye zvisina chepfu. Iyo adsorbent inoshandiswa mukushambadza ndeyemhando yepamusoro zeolite molecular sieve, iyo isiri-chepfu uye isingakuvadzi, yakagadzikana muzvisikwa, uye ine imwe sterilizing mhedzisiro, inogona kuchenesa mweya, uye iyo okisijeni inogadzirwa nekumanikidza swing adsorption inogona zvakare kushandiswa seokisijeni yekufema, kuperekedza hutano hwevanhu.

Iyo PSA oxygen concentrator inoshanda pakufema, yakanyarara uye isina ruzha. Zvichienderana nemusimboti wekuenzana adsorption ye adsorption kinetics, kupararira kwe nitrogen mu micropores ye zeolite molecular sieve yakakura kupfuura iyo yeokisijeni, uye iyo nitrogen inonyanya kushambadzirwa ne zeolite molecular sieve, uye okisijeni inopfumiswa muchikamu chegasi uye inonatswa nekubvisa sterilization uye guruva rekufemerwa kwevanhu.

• Kushandiswa pamba, hutano hwepamba. Tsiva mweya wakasviba nemhepo yakachena, yakachena, ine oxygen. Inozorodza uropi uye inodzinga kuneta.

• Zorora kumba. Vakwegura vane hurongwa hwekufema husina simba uye hutachiona, uye oksijeni yakachena uye yakakwana inobatsira kune vakwegura.

• Okisijeni yezvokurapa. Nekupa okisijeni kuvarwere, inogona kushandiswa kurapa chirwere chemoyo uye cerebrovascular, zvirwere zvekufema, chisingaperi chinovharira mabayo uye zvimwe zvirwere, pamwe neakanyanya hypoxic zvirwere senge gasi chepfu.

• Hutano: Inovandudza huwandu hweokisijeni yenzvimbo yemukati, zvinobudirira kuderedza kurwara kwepamusoro, kugadzirisa kurara uye kubvisa kuneta.

• Inonyaradza: Inobvisa kudiwa kwekupfeka masiki ekufema akawanda kana nasal oxygen tubes uye inoderedza miganhu yakasiyana-siyana yekufemerwa kweokisijeni yechinyakare.

• Zvitsva: Inogona adsorb traces yeCO₂, CO, H2S uye mamwe magasi anokuvadza mumhepo uye kuchenesa mhepo.

• Kunyarara: Kunyarara dhizaini, kuderera kweruzha uye kushanda kwepamusoro kuti kuve nechokwadi chekushanda kwakasununguka uye kunyarara.

• Yakachengeteka: Iyo okisijeni maitiro eiyo diffuse okisijeni jenareta ndeye yemuviri adsorption process, hapana makemikari reaction, hapana kusvibiswa kune zvakatipoteredza, girinhi uye kuchengetedzwa kwezvakatipoteredza, uye nyore kushandisa, yakachengeteka uye yakavimbika, uye yakaderera kushandiswa kwesimba.

• Modular, skid-mounted, yakanyarara uye inobudirira, inovimbisa nzvimbo yakasununguka uye yakanyarara yekushanda uye zvakasiyana-siyana zvekushandiswa kwemamiriro ezvinhu.

• Kuita kwakavimbika: Kupinza microcomputer control, zvizere otomatiki kushanda, hapana yakakosha kudzidziswa kwevashandisi, ingodzvanya bhatani rekutanga, inogona kushanda yega kuti iwane kuenderera mberi kwekugadzirwa kweokisijeni/nitrogen.

• Mari yekushanda yakaderera, nitrogen inogadzirwa mumaminitsi mashomanana mushure mekutanga, kushandiswa kwesimba kwakaderera, uye mari ye nitrogen yakaderera pane ye cryogenic air separation nitrogen production.

| Unit Type Tsanangudzo | LFPO-4A | LFPO-6A | LFPO-8A | LFPO-14A | LFPO-17A | LFPO-20A | LFPO-25A | LFPO-35A |

| Kugadzirwa kweOkisijeni (Nm3/H) | 4 | 6 | 8 | 14 | 17 | 20 | 25 | 35 |

| Oxygen Purity | ≥93% | |||||||

| Oxygen Pressure (Gauge Pressure) | 4.5-6.0Mpa | |||||||

| Nguva Yokutanga | ≤40 Min. | |||||||

| Kushandiswa kwePublic Engineering | Hapana mvura inotonhorera, chiridzwa mhepo midziyo. Iyo mudziyo skid kurodha kupihwa, iyo mushandisi saiti isina kuisirwa | |||||||

| Degree ye Automation | Zvakakwana otomatiki uye zvisina munhu kushanda | |||||||

| Safety Performance | Normal tembiricha uye yakaderera kumanikidzwa kushanda, yakakwirira kuchengeteka kushanda | |||||||

| Rated Power (kW) | 5.3 | 7.5 | 11.5 | 16 | 19.5 | 23 | 31 | 38.2 |

| Floor Space (Kureba*Kufara*Kureba) m3 | 1.6×1.4×2.4 | 2.2×1.6×2.4 | 2.4×1.8×2.4 | |||||

| Unit Type Tsanangudzo | LFPO-40A | LFPO-52A | LFPO-70A | LFPO-76A | LFPO-83A | LFPO-120A | LFPO-145A | LFPO-190A | LFPO-225A |

| Kugadzirwa kweOkisijeni (Nm3/H) | 40 | 52 | 70. | 76 | 83 | 120 | 145 | 190 | 225 |

| Oxygen Purity | 93% | ||||||||

| Oxygen Pressure(g) | 4.5-6.0Mpa | ||||||||

| Nguva Yokutanga | ≤45 Min. | ||||||||

| Kushandiswa kwePublic Engineering | Hapana mvura inotonhorera, chiridzwa mhepo midziyo. Iyo mudziyo skid kurodha kupihwa, iyo mushandisi saiti isina kuisirwa | ||||||||

| Degree ye Automation | Zvakakwana otomatiki uye zvisina munhu kushanda | ||||||||

| Safety Performance | Normal tembiricha uye yakaderera kumanikidzwa kushanda, yakakwirira kuchengeteka kushanda | ||||||||

| Rated Power(kW) | 47.2 | 58 | 79 | 94 | 114 | 137.5 | 167 | 210 | 260 |

| Floor Space (Kureba*Kufara*Kureba) m3 | 3.0×2.4×2.6 | 3.5×2.4×2.6 | 4.0×2.4×2.8 | 4.8×2.6×2.8 | |||||